Broyue Storage Tanks

GMP-Compliant, Customizable Solutions for Critical Liquid Storage

Product Overview

Broyue sanitary storage tanks are engineered for pharmaceutical, biotech, and food industries, offering high-purity liquid storage with full compliance to GMP, CIP/SIP, and pressure vessel standards.

Key Features:

- Capacity Range: 600L to 20,000L (custom designs available)

- Materials: 304/316L stainless steel, Ra ≤0.2–0.6μm mirror polish

- Standards: GB150-2011 (pressure vessels), NB/T 47003.1-2009 (welded tanks), GMP certified

Technical Specifications

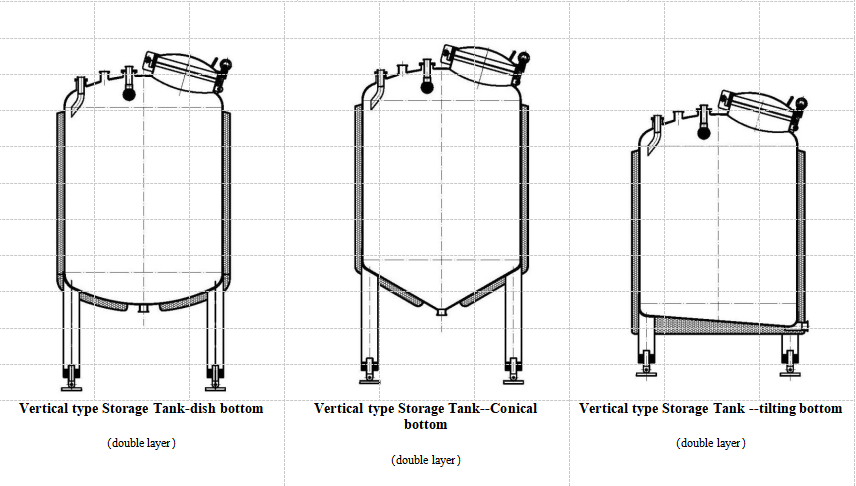

Design Types Vertical/Horizontal (round/square options)

Head Types: Ellipsoidal, spherical, conical (customizable)

Insulation: Rock wool (standard) / Polyurethane(high-efficiency)

Surface Finish: Internal: Ra ≤0.6μm /External: Mirror/brushed/sandblasted

Pressure Rating: Custom (ASME/DIN/GB standards)

Temperature: -20°C to +150°C (higher with special jackets)

Design & Construction

- Hygienic Tank Configurations

- Single-layer: Standard storage

- Double-layer: Insulated tank + insulated bottom head

- Jacketed: Heating/cooling jacket + insulation

- No Dead-Leg, Easy-to-Clean Structure

- Smooth radius transitions (no corners)

- Tri-clamp connections (sanitary fittings)

- CIP/SIP compatible (self-draining design)

- Customizable Options

- Top/Bottom Heads: Ellipsoidal, spherical, dished, or flat

- Mounting: Fixed legs, adjustable feet, or mobile skids

Optional Accessories

✔ Sterile air vent filters (0.2μm PTFE)

✔ Digital/pressure gauges (with sanitary seals)

✔ Sight glasses & level sensors (radar/ultrasonic)

✔ CIP rotating spray balls (360° coverage)

✔ Manways & nozzles custom sizes/locations)

Applications

Pharmaceutical:*WFI (Water for Injection), buffer storage, API solutions

Biotech: Cell culture media, fermentation liquids

Food & Beverage: Milk, juice, syrup, edible oil storage

Cosmetics: Emulsions, solvents, fragrances

Why Choose BROYUE?

GMP-compliant: Full documentation (DQ/IQ/OQ support)

Zero contamination risk: Orbital welding available

Custom engineering: Tailored to your process needs

Customization Services

- Material upgrades: 316L, duplex steel, Hastelloy

- Special coatings: PTFE-lined for aggressive chemicals

- Automation: Integrated PLC controls, IoT monitoring

Design Parameter

| Design pressure | ATM~1.0MPa |

| Design temperature | 0℃~160℃ |

Material

| Liner | 304、316L |

| Insulation | Rock wool or PU |

| Legs | 304 |

Surface Finish

| Finish type | Mechanical/electrolytic polishing,

sand blasting,pickling |

| Polishing precision | Inner surface 0.4μm,

Outside surface 0.6μm |

Connection

| In-outlet | Tri-clamp, Flange |

Storage Tank Structure

Mobile Storage Tank Structure

Specs data

| Parameters | Model | BYST—600 | BYST—1000 | BYST—2000 | BYST—3000 | BYST—4000 | BYST—5000 | |

| Effective volume:L | 600 | 1000 | 2000 | 3000 | 4000 | 5000 | ||

| Tank | Diameter:mm | Φ900 | Φ1100 | Φ1300 | Φ1600 | Φ1700 | Φ1800 | |

| Height/Length:mm | 900 | 1000 | 1500 | 1500 | 1800 | 1800 | ||

| Agitator | Power:kW | 1.1 | 1.5 | 2.2 | 2.2 | 3 | 4 | |

| RPM:r/min | 60(Paddle impeller)(Can adjust the design according to the customer’s usage) | |||||||

| BYST—6000 | BYST—8000 | BYST—10000 | BYST—12000 | BYST—15000 | BYST—20000 | |||

| 6000 | 8000 | 10000 | 12000 | 15000 | 20000 | |||

| Φ1900 | Φ2000 | Φ2200 | Φ2400 | Φ2600 | Φ2800 | |||

| 2000 | 2200 | 2400 | 2500 | 2700 | 3000 | |||

| 4 | 5.5 | 7.5 | 7.5 | 11 | 11 | |||

| 60(Paddle impeller)(Can adjust the design according to the customer’s usage) | ||||||||