Tube Filter is a improved small in-line strainer which can remove a small amount of solid particles in the liquid, also can protect compressor, pump, instruments and other equipment to work normally.

Broyue Tube Filter adopts multiple polishing processing steps to ensure that the interface Ra reach to 0.6um close to sanitary level. All of the surface is mirror polished.

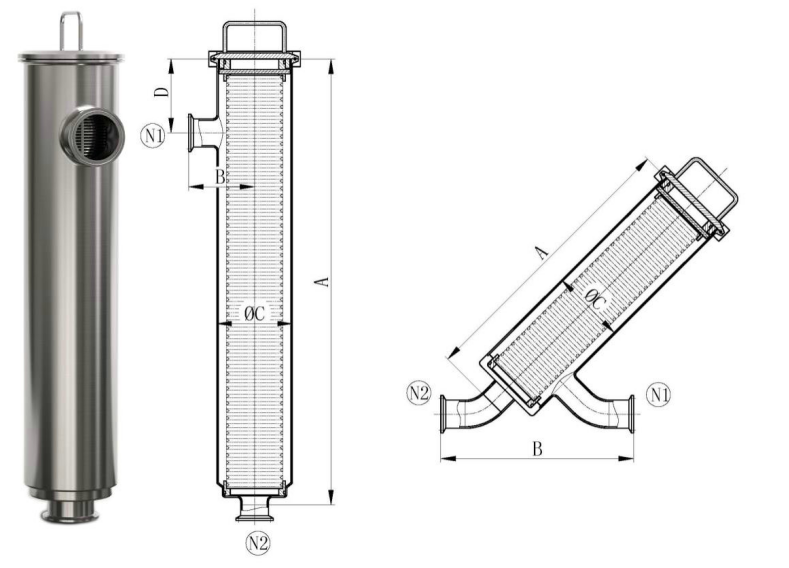

Broyue hygienic in-line filters are suitable for the filtering and straining of process liquids in a wide range of sanitary applications. All stainless steel product contact surfaces are polished to a hygienic standard and all seals are manufactured from FDA compliant materials. Standard execution is the right angled 90° design but “Y-type” execution can also be offered. Standard end connections are butt weld for tube but other connection options are also available. On request the filter housing can be delivered with heating jacket.

For applications requiring only coarse filtration (1mm, 1.5mm, 2mm, 3mm, etc.) the filters are offered with a filtering insert manufactured from perforated stainless steel plate.

Where finer filtration is required (e.g. 50 micron, 100 micron, 150 micron, 200 micron, 500 micron, etc.) the filters are offered with a slotted tube or wedge wire type filtering insert. The wedge wire type filtering insert consists of v-shaped profiles welded very accurately on to cross support bars allowing precise control of the distance between the v-shaped profiles. This distance is referred to as the slot opening.

The standard execution offered by Broyue is for flow from “inside to outside” of the filtering insert. On request the opposite flow direction can also be offered.

Wedge wire filtration offers the following advantages over traditional stainless steel “gauze & perforated plate” or “sock” type filter inserts:

Greater mechanical strength

Greater pressure resistance

Suitability for manual cleaning or for automatic cleaning with reverse flow (backflushing)

Improved abrasion and vibration resistance

Particles don’t become trapped between different layers (as can occur with perforated plate and gauze combinations)

Substantially longer screen life

Greater usable surface area

The filtering inserts (perforated plate and wedge wire types) are also suitable for retrofitting directly to housings from some other manufacturers.