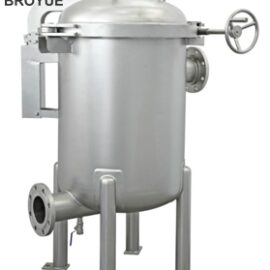

Sanitary Liquid Filtration Housing

Hygienic Design & ComplianceBroyue sanitary filters are engineered to meet the strictest hygienic standards, featuring: - Dead-space-free construction for complete drainage and zero product retention - Fully compliant with GMP requirements for high-cleanliness applications - 304/316L stainless steel construction with tri-clamp (TC) inlet/outlet connections - Fully disassemblable design: Removable housing and cartridge plate enable 360° cleanability - Ultra-smooth surface finish: Mirror polish (Ra <0.4μm) on all housing internal surfaces - Multi-brand compatibility: Supports Pall, Millipore, and 3M filter cartridges

Standard Specifications

- Cartridge lengths: 10", 20", 30", 40"

- Connection types: 226 ,222 and DOE

- Operating pressure: Up to 10 bar (custom high-pressure models available)

Product Series

1. Single-Cartridge Sanitary Filters

- Ideal for: Small-batch processing (craft breweries, wineries, lab-scale applications)

- Key features:

- Modular design allows multi-stage filtration when connected in series

- Precision filtration from 0.1μm to 100μm via interchangeable cartridges

- Compact footprint

- Multi-Cartridge Sanitary Housings

- Capacity: Usually 3-15 cartridges (can 56cartridges configurable for ultra-high flow rates)

- Advanced hygienic design:

- Rotating-lift arm mechanism for easy cartridge replacement

- Top/bottom bolted openings for full disassembly

- 226/222/DOE-compatible cartridge plates (customizable)

- Super-polished (Ra <0.4μm) fluid contact surfaces

Industry Applications

Pharmaceutical: Pre-filtration of antibiotic solutions, buffer prep

Food & Beverage: Beer/wine clarification, bottled water sterilization

Oil & Gas: Injection water filtration for enhanced recovery

Electronics: UPW/DI water pre-filtration for chip manufacturing

Chemical: Solvent purification, acid/alkali processing

Customization & OEM Services

- Material options: SS304, 316L, duplex steels, alloy coatings

- Surface finish: Mechanical polishing, Electropolished

- OEM support:

- Brand-specific labeling/packaging

- Custom documentation (DQ/IQ/OQ protocols)

- Validation assistance (FDA, EU GMP)

Certifications:

✔ FDA 21 CFR 177.2600

✔ EHEDG compliant

✔ 3-A Sanitary Standards

Operating Conditions

| Max operating pressure | 1.0MPa |

| Max operating temperture | 150℃ |

| Disinfect | Online or steam sterilization:

121℃/30min |

Material

| Shell | 304、316L |

| Vent/ Drain valve | 304 |

| Quick-open、Stabilizer blade | 304 |

| O-ring | EPDM, PTFE, Viton, Silicone |

Connection

| Shell connection | Tri-clamp |

| N1, N2 In-outlet | Tri-clamp |

| N3 Pressure gauge (option) | 1.5” Tri-clamp |

| N4 Vent valve (option) | M6 Thread |

| N5 Drain valve(option) | M6 Thread |

| Cartridges connection | 222type, 226type |

Surface Finish

| Finish type | Mechanical/ Electrolytic polishing |

| Polishing precision | Inner surface Ra≤0.3μm ,

Outside surface Ra≤0.4μm. |

Selection Table

| [Qty. of cartridge] | [Model of cartridge] | [Cartridges connection] | [Shell material] | [In-outlet Connection] | [O-ring] | |

| BYSCF | 5R | 20 | S | 4 | K | E |

| 1R=1pcs

3R=3pcs |

10=10”Cartridge | S=226 (sanitary grade) | 4= 304 | K=Tri-clamp | E=EPDM | |

| 5R=5pcs | 20=20”Cartridge | T=222 (sanitary grade) | 6= 316L | P=PTFE | ||

| 7R=7pcs | 30=30”Cartridge | D=DOE(industrial grade) | V=Viton | |||

| 9R=9pcs | 40=40”Cartridge | S=Silicone | ||||

| 12R=12pcs |