Lenticular Filter Housings

Product Highlights

- Engineered for challenging fluids: Ideal for high solids-load processing or pre-filtration prior to sterile membrane filtration

- Premium construction: 304/316L stainless steel with sanitary electropolish (Ra <0.3μm)

- Hygienic design & fabrication

Standard Configuration

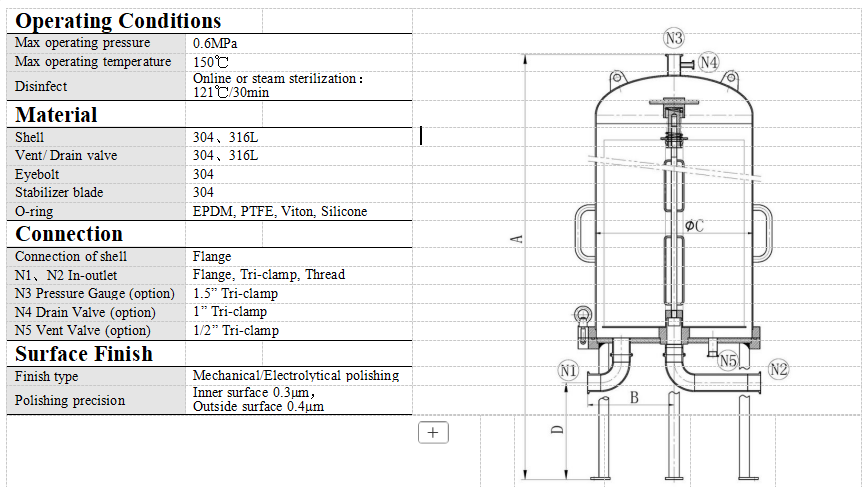

Body Material: 304/316L SS (Electropolished)

Process Connections: Tri-clamp

Instrumentation: Sanitary pressure gauge + 2 butterfly valves

Filter element Options: 12" (1.8m²) / 16" (3.6m²) stackable modules

Optional Accessories: Support grid & backflush deflector plate

*Note: Filter modules sold separately (available upon request)*

Technical Advantages

✔ Superior solids-handling – Unique lenticular stack design resists clogging

✔ Validation-ready – Compliant with FDA 21 CFR & EHEDG standards

✔ Easy maintenance – Full disassembly capability for CIP/SIP

✔ Process flexibility – Configurable as:

- Depth filter (with diatomaceous earth/cellulose modules)

- Pre-filter for sterile membranes

- Final polishing filter

Industry Applications

Food & Beverage

- Clarification: Syrups, spirits, wine/beer

- Juice processing: Concentrate pre-filtration

- Edible oils: Olive oil final polishing

Pharma/Cosmetics

- API solutions pre-filtration

- Buffer preparation in biopharma

- Cosmetic emulsions clarification

Industrial

- Chemical slurry processing

- Wastewater solids removal

- Pre-membrane protection

Why Choose Broyue Lenticular Housings?

- Proven in high-viscosity fluids – Patent-pending flow distribution design

- Reduced changeout frequency – 30% longer service life vs. conventional housings

- Global certifications:

- 3-A Symbol #09-03

- CE PED 2014/68/EU

- ASME BPE (Bio-Processing Equipment)

Contact our engineers for application-specific sizing!

Selection Table

| [Qty. of Filter Stacks] | [Model of Filter Stacks] | [Shell Material] | [In-outlet connection] | [O-ring] | |

| BYLF | 1B | 12 | 4 | F | E |

| 1B=1pc | 12=12” Filter Stacks | 4= 304 | F= Flange | E=EPDM | |

| 2B=2pcs | 16=16” Filter Stacks | 6= 316L | K= Tri-clamp | P=PTFE | |

| 3B=3pcs | V=Viton | ||||

| 4B=4pcs | S=Silicone |