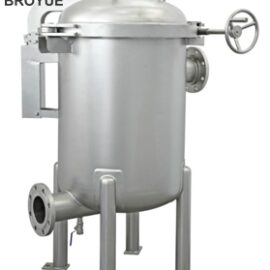

Bag Filter Product Introduction

Bag filters are one of the most widely used filtration devices in industrial applications, primarily employed for pre-filtration and fine filtration in industries such as food & beverage, water treatment, bioengineering, new energy batteries, and chemical processing. Broyue offers single-bag and multi-bag filters to meet varying flow rate requirements, with support for customized designs and OEM manufacturing.

- Product Series

(1) Single-Bag Filter

- Compatible Bag Sizes: No. 1, 2, 3, and 4 standard filter bags

- Features:

- Adjustable leg height for flexible on-site installation

- Compact structure, suitable for small to medium flow rates

- Easy bag replacement, minimizing maintenance costs

(2) Multi-Bag Filter

- Standard Configuration: No. 02 filter bags (other sizes customizable)

- Bag Capacity: 2-24 bags (standard: 2-12 bags, expandable for high-flow needs)

- Features:

- High-flow processing capability, ideal for large-volume applications

- Modular design, allowing flexible adjustment of bag quantity

- Parallel/series installation for multi-stage filtration

- Key Advantages

(1) Premium Materials & Precision Manufacturing

- Body Material: High quality Stainless steel 304 / 316 (corrosion-resistant, high-temperature resistant)

- Welding Technology: High-precision welding for optimal sealing

- Surface Finish: Fine polishing, compliant with GMP/FDA standards

Flexible Installation Options

- Fixed Mounting: Adjustable legs for versatile setups

- Mobile Configuration: Compatible with carts + pumps for portability

- Multi-Stage Series Connection: Enables coarse → fine graded filtration

(3) Broad Applicability

- Standard Operating Pressure: 1MPa

- Temperature Resistance: ≤150°C (higher-temperature models available upon request)

- Compatible Media: Water, organic solvents, acids/alkalis, food-grade fluids, etc.

- Industry Applications

Food & Beverage: Syrup filtration, juice clarification, beer pretreatment

Water Treatment: Industrial wastewater pre-filtration, RO system pre-treatment

Bioengineering: Fermentation broth filtration, cell culture media purification

New Energy Batteries: Electrolyte filtration, lithium battery slurry processing

Chemical Processing: Solvent fine filtration, catalyst recovery, acid/alkali purification

- Customization & OEM Services

- Material Customization: Options include 304, 316L, titanium alloy, PP/PTFE lining, duplex 2205, etc.

- Size Customization: Non-standard dimensions, special ports, unique structural designs

- Functional Upgrades: high-temperature/high-pressure

- OEM Branding: Supports custom branding and packaging

Material

| Shell | 304, 316L, Duplex Steel 2205 |

| Non-liquid contact parts | 304 |

| Seal O-ring | EPDM, PTFE, Viton, Silicone |

Nozzles

| Shell &cover connection | Flange |

| In-outlet | Flange, Tri-clamp, Thread, Butt-weld |

| Pressure Gauge

(option) |

1” Tri-clamp

(3#Bag /4#Bag) |

| Vent Valve (option) | 1/2” Tri-clamp |

Surface Finish

| Finish type | Mechanical polishing, electrolytic polishing, sandblasting, pickling |

| Polishing precision | Standard of MP: Inner surface Ra≤0.6μm ,Outside surface Ra≤0.8μm.

0.6μm |

Selection Table

| [Qty. of Bag Filter] | [Model of Bag Filter] | [Shell Material] | [In-outlet connection] | [O-ring] | ||

| BYBF | 1P | 2S | 4 | F | E | |

| 2P=2pcs | 7P=7pcs | 1S=1# Bag:Φ180 x 430 | 4= 304 | F= Flange | E=EPDM | |

| 3P=3pcs | 9P=9pcs | 2S=2# Bag:Φ180x 810 | 6= 316L | TC= Tri-clamp | P=PTFE | |

| 4P=4pcs | 12P=12pcs | 3S=3# Bag:Φ105 x 230 | S= SMS | V=Viton | ||

| 4S=4# Bag:Φ105x 380 | ||||||