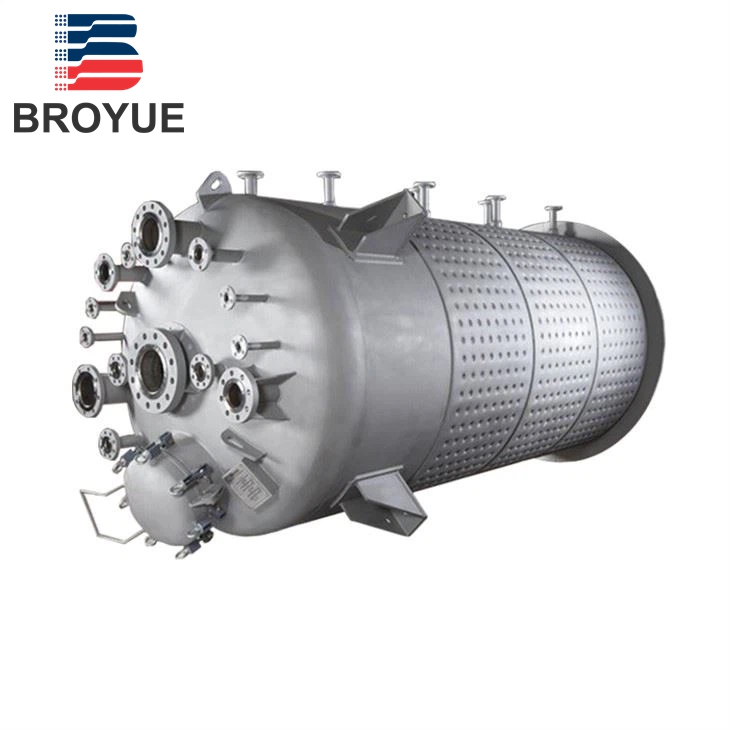

Reaction Vessels**

High-Performance Reactors for Chemical, Pharma & Food Industries

Certified Heavy-Duty Design

- Compliance:

- GB150-2011 (Pressure Vessel) + NB/T 47003.1-2009 (Welded Tanks)

- Robust Construction:

- 316L/304 stainless steel (electropolished Ra ≤0.4μm)

- Orbital welding for critical joints (PED 2014/68/EU compliant)

Technical Specifications

Capacity: 600L–20,000L (custom designs available)

Pressure Rating: Up to 5MPa (custom high-pressure options)

Temperature: -50°C to +300°C (with special jackets)

Heating/Cooling: Steam, thermal oil, electric, or hybrid

Agitation: 0–300 RPM (variable frequency drive)

Key Features

- Advanced Process Flexibility

- Jacket Types:

- Dimpled jacket: For high-pressure steam (>1.5MPa)

- Half-coil jacket: Uniform heat transfer

- Plate coil: Rapid temperature changes

- Impeller Options:

- Anchor/Frame: High-viscosity mixing (up to 500,000 cP)

- Turbine: Gas-liquid dispersion (e.g., hydrogenation)

- Precision Control Systems

- Automated parameter tracking: Temperature (±0.5°C), pressure (±1%), pH (±0.1)

- Safety systems: Overpressure relief, emergency cooling

- Hygienic & Maintenance-Friendly

- CIP/SIP ready: Tri-clamp connections, spray ball integration

- Quick-change seals: Double mechanical seals (API 682 compliant)

Optional Configurations

✔ Aseptic vent filters (0.2μm PTFE)

✔ Explosion-proof motors (ATEX/IECEx)

✔ In-situ cleaning validation ports

✔ ATR/FTIR probes for real-time reaction monitoring

Applications

Pharmaceutical: API synthesis, crystallization, lyophilization

Fine Chemicals: Hydrogenation, polymerization, alkylation

Food & Beverage: Emulsification, flavor compounding

Energy: Biofuel catalysis, lubricant synthesis

Customization Services

- Material upgrades: Hastelloy, zirconium, tantalum linings

- Specialized impellers: CFD-optimized for shear-sensitive fluids

- Modular skid-mounted units for mobile production

Contact our chemical engineering team for process-specific solutions!

This version:

- Targets advanced users with technical depth (e.g., API 682 seals)

- Highlights safety/automation for hazardous processes

- Includes real-world viscosity ranges for impeller selection

- Shows regulatory readiness (SIL-3, ATEX)

- Adds credibility with engineering heritage claim

Would you like me to:

- Compare jacket types in a thermal performance table

- Add P&ID snippets for common configurations

- Include TUV certification details- Request CFD flow simulation reports

- Get material compatibility charts

- Discuss explosion-proof requirements

Specs data

| Parameters | Model | BYFYF—600 | BYFYF—1000 | BYFYF—2000 | BYFYF—3000 | BYFYF—4000 | BYFYF—5000 | |

| Effective volume:L | 600 | 1000 | 2000 | 3000 | 4000 | 5000 | ||

| Tank | Diameter:mm | Φ900 | Φ1100 | Φ1300 | Φ1600 | Φ1700 | Φ1800 | |

| Height:mm | 900 | 1000 | 1500 | 1500 | 1800 | 1800 | ||

| Mixing | Power:kW | 1.1 | 1.5 | 2.2 | 2.2 | 3 | 4 | |

| RPM:r/min | 200(propeller)or 60(anchor type)(Can adjust the design according to the customer’s usage) | |||||||

| BYFYF—6000 | BYFYF—8000 | BYFYF—10000 | BYFYF—12000 | BYFYF—15000 | BYFYF—20000 | |||

| 6000 | 8000 | 10000 | 12000 | 15000 | 20000 | |||

| Φ1900 | Φ2000 | Φ2200 | Φ2400 | Φ2600 | Φ2800 | |||

| 2000 | 2200 | 2400 | 2500 | 2700 | 3000 | |||

| 4 | 5.5 | 7.5 | 7.5 | 11 | 11 | |||

| 200(propeller)or 60(anchor type)(Can adjust the design according to the customer’s usage) | ||||||||

| The above-mentioned data is the standard. It can be customized according to customer’s requirements. | ||||||||