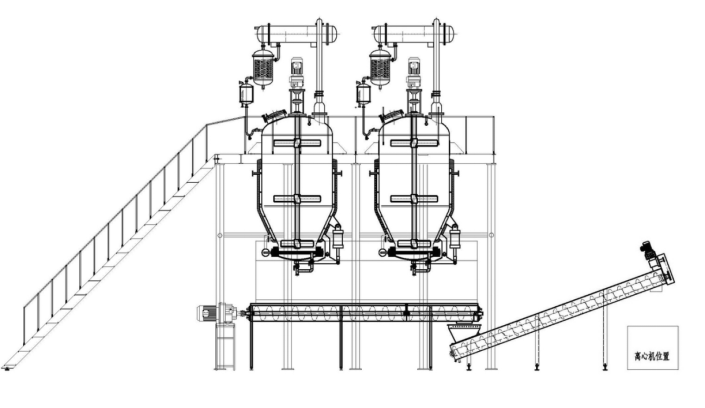

Pilot-Scale Extraction Systems - Modular GMP-Compliant Solutions

System Overview

Broyue's integrated extraction modules provide scalable, GMP-compliant processing for botanical extracts, pharmaceuticals, and essential oils. Our systems bridge R&D to production with flexible operation modes.

Key Components

- Core Processing Modules

- Extraction Vessel:

- Jacketed heating (steam/oil thermal fluid)

- Built-in anti-foaming system

- Agitation options: Anchor/Turbine/Recirculation

- Evaporation-Condensation Unit:

- Falling film/centrifugal evaporators

- Low-temperature condensation (-10°C optional)

- Separation System:

- Liquid-liquid separators (essential oil recovery)

- Cyclone filters for particulate removal

- Support Systems

- Automated Controls:

- PLC/HMI with recipe management

- Real-time monitoring: Density, refractive index, pH

- Material Handling:

- Pneumatic conveying for herb input

- Slag discharge with screw conveyor

process capabilities

| Function | Technical highlights | Typical applications |

| Extraction | Dynamic /static maceration/percolation | Cannabinoids, herbal concentrates |

| Concentration | 40°C low-T vacuum evaporation | Heat-sensitive compounds |

| Distillation | Ethanol/water/solvent recovery (≥95%) | Essential oils, tinctures |

| Precipitation | In-line chilling (+2°C to -5°C) | Protein purification |

Scalability Options

Pilot Systems (R&D Focus)

- Compact skid-mounted designs

- Quick-change vessel configurations

- Data logging for process development

Production Systems

- Multi-vessel parallel operation (2-8 units)

- Centralized automation:

- OEE tracking

- CIP integration

- Custom layouts for existing facilities

GMP Design Features

✔ Sanitary construction: Orbital welding, drainable angles

✔ Material traceability: Full documentation packages

✔ Validation support: IQ/OQ/PQ protocols

✔ Cleanability: CIP-ready with spray devices

Industry Applications

- Phytopharmaceuticals: Active ingredient extraction

- Nutraceuticals: Standardized herbal extracts

- Essential Oils: Terpene fractionation

- Biotech: Natural product isolation